Woven Wire Screen

Price 900 INR/ Meter

Woven Wire Screen Specification

- Surface Treatment

- Galvanized, Powder Coated

- Hole Shape

- Square

- Length

- As per requirement (customizable)

- Aperture

- 1 mm to 100 mm

- Wire Gauge

- Mild steel wire gauge 6-20 SWG

- Product Type

- Woven Wire Screen

- Mesh Type

- Crimped Mesh

- Mesh Style

- Woven Mesh

- Material

- Mild Steel, Stainless Steel, GI

- Alloy

- Low carbon, High carbon

- Application

- Mining, Quarry, Construction, Filtration, Sieving

- Dimensions

- Custom sizes available

- Wire Diameter

- 0.025 mm to 4 mm

- Weight

- Variable as per size and gauge

- Color

- Silver

- Tensile Strength

- High tensile strength for heavy-duty screening

- Operating Temperature

- Up to 400°C depending on material

- Open Area Percentage

- Up to 80%

- Standard Roll Length

- 15 m, 30 m, or as required

- Usage

- Screening, Grading, Separating, Filtering

- Standard Roll Width

- 1 m, 1.2 m, 1.5 m

- Corrosion Resistance

- Yes, depending on surface treatment

- Edge Type

- Folded/Hooked/Plain

Woven Wire Screen Trade Information

- Minimum Order Quantity

- 100 Meter

- Main Domestic Market

- All India

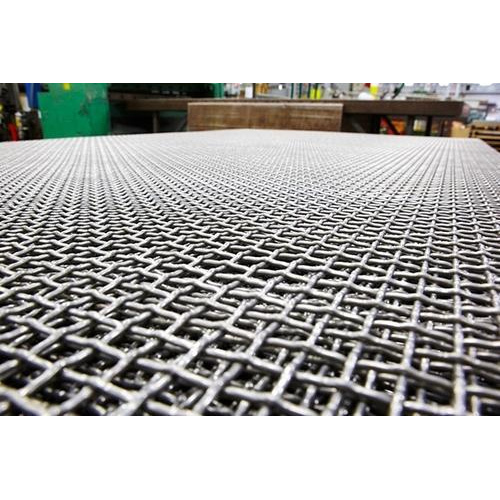

About Woven Wire Screen

Key Features & Applications of Woven Wire Screen

Our Woven Wire Screen is widely used at sites such as quarries, mines, construction zones, and filtration plants. It features high tensile strength and is designed to handle rigorous and continuous operation. The screen serves various processes, including screening, grading, separating, and filtering materials. Its customizable mesh, edge types, and wire gauges allow for versatile use across different machine types and industrial settings, making it a preferred choice for heavy-duty and precision screening tasks.

FOB, Certifications & Supply - Ensuring Secure Delivery

Enjoy flexible transport services with efficient worldwide shipping from major Indian FOB ports. Ask us for an instant quotation based on your specifications and location. Our Woven Wire Screens come with relevant industry certifications, assuring you of quality and performance. With a remarkable supply ability, your bulk and custom orders are fulfilled on time. Secure shipping and packaging guarantee your product arrives safely, allowing you to focus on your operations with total confidence and peace of mind.

FAQ's of Woven Wire Screen:

Q: How can I customize the woven wire screen for my specific needs?

A: You can specify the edge type, mesh size, wire gauge, aperture, roll width and length, hole shape, and surface treatment when placing your order, ensuring the woven wire screen perfectly matches your equipment and application.Q: What are the main applications for a woven wire screen?

A: Woven wire screens are commonly used for screening, filtering, grading, sieving, and separating materials in industries such as mining, quarrying, construction, and filtration due to their durability and high open area.Q: Where can I use the woven wire screen?

A: These screens are suitable for a variety of sites, including mines, quarries, construction projects, as well as industrial filtration and sieving operations, thanks to their robust construction and versatility.Q: What is the process for obtaining a quotation and arranging transport?

A: Simply contact us with your specific requirements and preferred FOB port. We will provide an accurate quotation and organize secure shipping with reliable transport partners to ensure prompt delivery.Q: What is the benefit of choosing a high tensile strength woven wire screen?

A: High tensile strength ensures the screen withstands heavy-duty applications and repeated stress, reducing the risk of damage and extending its operational life, which translates to cost savings and reliable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Screen Category

Tungsten Wire Screen

Price 550 INR / Meter

Minimum Order Quantity : 100

Mesh Type : Other , Fine Mesh

Material : Other, Tungsten

Surface Treatment : Polished

Wire Diameter : 0.2 mm

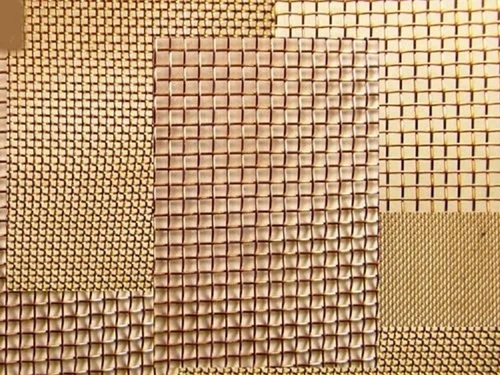

Phosphor Bronze Wire Screen

Price 2200 INR / Meter

Minimum Order Quantity : 100

Mesh Type : Other , Fine Mesh

Material : Other, Phosphor Bronze

Surface Treatment : Polished

Wire Diameter : 0.3 mm 0.71 mm

Iron Wire Screen

Price 420 INR / Meter

Minimum Order Quantity : 100

Mesh Type : Other , Wire Mesh

Material : Iron

Surface Treatment : Other, Galvanized or plain

Wire Diameter : 0.5 mm to 2 mm

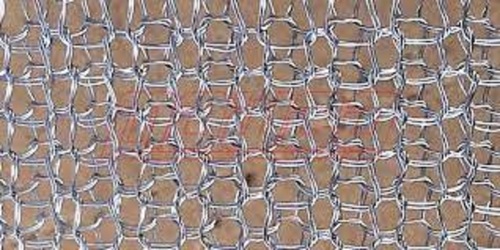

Stainless Steel Knitted Wire Screen

Price 450 INR / Meter

Minimum Order Quantity : 100

Mesh Type : Other , Fine Mesh / Medium Mesh

Material : Other, Stainless Steel (commonly SS304, SS316, or specified grade)

Surface Treatment : Other, Plain, Degreased, or Electropolished

Wire Diameter : 0.15 mm 0.55 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry