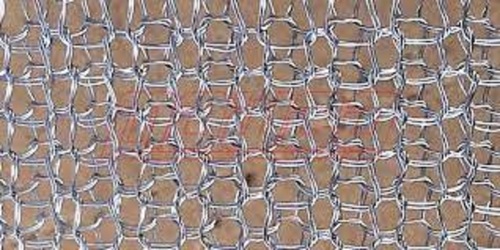

Stainless Steel Knitted Wire Screen

Price 450 INR/ Meter

Stainless Steel Knitted Wire Screen Specification

- Hole Shape

- Square or Rectangular (as per knitting pattern)

- Aperture

- 1 mm 5 mm (customizable)

- Surface Treatment

- Plain, Degreased, or Electro-polished

- Wire Gauge

- Customized as per requirement (commonly 0.15 mm 0.55 mm)

- Length

- 10 m, 30 m, 50 m, or customized

- Product Type

- Knitted Wire Mesh / Screen

- Mesh Type

- Fine Mesh / Medium Mesh

- Mesh Style

- Knitted Mesh

- Material

- Stainless Steel (commonly SS304, SS316, or specified grade)

- Alloy

- SS304, SS316, or upon request

- Application

- Filtration, Demister Pads, Air-Gas-Liquid Separation, Shielding, Noise Reduction

- Dimensions

- Width: 10 mm 600 mm (customizable)

- Wire Diameter

- 0.15 mm 0.55 mm

- Weight

- As per size and mesh density (typically 0.5 kg/m 2.5 kg/m)

- Color

- Silver (natural stainless steel finish)

- MOQ

- Flexible (subject to availability and order size)

- Knitting Type

- Flat or Ginning as per requirement

- Thickness

- 2 mm 20 mm (custom range possible)

- Packing

- Rolls or Cut Lengths, individually wrapped or bundled

- Temperature Resistance

- Up to 800C (varies by alloy)

- Layering

- Available as single or multi-layer

- Edge Finish

- Raw Cut, Welded, or Seamed

- Corrosion Resistance

- Excellent, suitable for harsh & acidic environments

Stainless Steel Knitted Wire Screen Trade Information

- Minimum Order Quantity

- 100 Meter

- Main Domestic Market

- All India

About Stainless Steel Knitted Wire Screen

Applications, Advantages, and Usage of Stainless Steel Knitted Wire Screen

Our Stainless Steel Knitted Wire Screen is perfectly suited for filtration, demister pads, noise reduction, and air-gas-liquid separation in industrial, chemical, and environmental settings. Its primary competitive advantages include adaptability to custom sizes and alloys, robust temperature and corrosion resistance, and varied mesh types for specific use cases. By choosing this product, customers secure reliable performance and longevity, especially where other materials would fail under demanding conditions.

FOB Port, Market Reach & Delivery for Stainless Steel Knitted Wire Screen

Handed over typically from major Indian FOB ports, our Stainless Steel Knitted Wire Screen reaches both the pan-India marketplace and international export zones. The asking price is competitive and is determined by the screen's specifications, mesh density, and raw material costs. Managing your expenditure is easy with flexible MOQ terms and custom orders. Expect delivery within standard industrial timelines-exact time frames depend on order size and custom requirements.

FAQ's of Stainless Steel Knitted Wire Screen:

Q: How is the Stainless Steel Knitted Wire Screen manufactured for varying applications?

A: The screen is produced using high-quality stainless steel wires, knitted by either flat or ginning methods. Different mesh styles, wire gauges, and layers are tailored to meet diverse filtration, separation, and shielding needs.Q: What are the primary benefits of using this product in harsh or acidic environments?

A: Its excellent corrosion and temperature resistance-up to 800C (varying by alloy)-ensure reliable, long-lasting performance where normal wire screens may deteriorate, making it ideal for chemical facilities or industrial settings.Q: When should I choose single-layer versus multi-layer knitted wire screens?

A: Select single-layer screens for lighter filtration and noise reduction, while multi-layer configurations are best for applications needing greater structural integrity, finer filtration, or aggressive operating conditions.Q: Where are these knitted wire screens commonly installed?

A: They are widely used in demister pads, industrial filtration, air-gas-liquid separation, and areas requiring electromagnetic or noise shielding-across sectors such as chemical, environmental, and manufacturing.Q: What is the process for customizing size and aperture in these screens?

A: Contact our sales team with your precise requirements. You may specify dimensions, thickness, mesh type, wire gauge, and aperture size. We then produce and package the screens as rolls or cut lengths to your specifications.Q: How does the surface treatment affect the wire screen's performance?

A: Surface treatments such as degreasing or electropolishing improve cleanliness, corrosion resistance, and longevity, while a plain finish delivers the natural aesthetic and basic functional durability of stainless steel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Screen Category

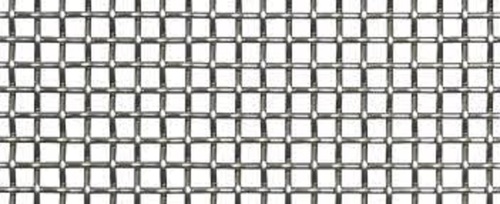

Square Wire Screen

Price 500 INR / Meter

Minimum Order Quantity : 100

Aperture : 2 mm to 25 mm

Application : Other, Sieving, Filtration, Fencing, Quarry Industries

Alloy : Low Carbon, High Carbon or Stainless Steel

Hole Shape : Other , Square

Inconel Wire Screen

Price 450 INR / Meter

Minimum Order Quantity : 100

Aperture : 0.5mm 10mm

Application : Other, Filtration, Separation, Screening, Chemical Industry

Alloy : Inconel 600 / 625

Hole Shape : Other , Rectangular / Square

Monel 400 Wire Screen

Price 425 INR / Meter

Minimum Order Quantity : 100

Aperture : 0.5 mm 10 mm

Application : Other, Filtration, Sieving, Chemical Industry, Marine

Alloy : Monel 400

Hole Shape : Other , Square, Rectangular

Tungsten Wire Screen

Price 550 INR / Meter

Minimum Order Quantity : 100

Aperture : 0.15 mm

Application : Other, Filtration, Laboratory Screening, High Temperature Applications

Alloy : Pure Tungsten

Hole Shape : Other , Square

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry