Call: 07971189685

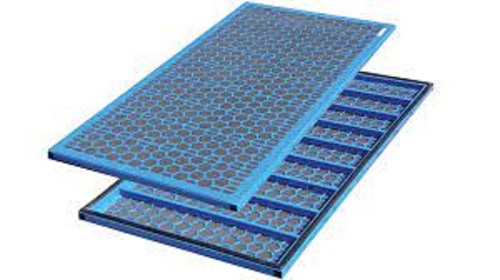

Stainless Steel Screen

Price 1500 INR/ Foot

MOQ : 50 Feet

Stainless Steel Screen Specification

- Surface Treatment

- Polished / Unpolished

- Wire Gauge

- 14 - 28 SWG

- Aperture

- 0.5 mm to 10 mm

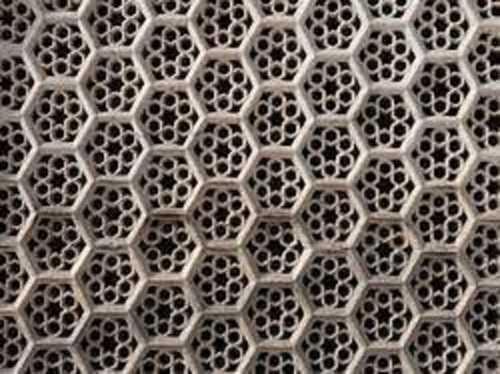

- Hole Shape

- Square / Rectangular

- Length

- As per requirement (Standard is 30 meters)

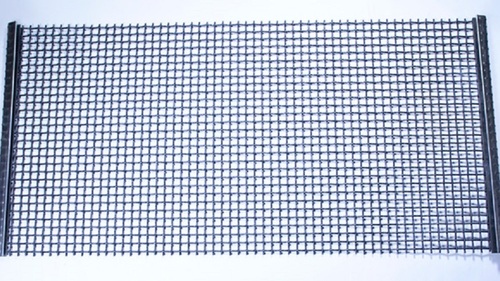

- Product Type

- Wire Mesh Screen

- Mesh Type

- Stainless Steel Screen

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel (SS304, SS316, SS316L)

- Alloy

- SS304 / SS316 / SS316L

- Application

- Filtration, Sieving, Mining, Chemical, Food Processing

- Dimensions

- Width: 1m, 1.2m, 1.5m, Custom sizes available

- Wire Diameter

- 0.3 mm to 2.0 mm

- Weight

- Varies as per dimensions and wire gauge

- Color

- Silver

- Corrosion Resistance

- Excellent, suitable for harsh environments

- Standard Packing

- Rolls, Wrapped with waterproof paper and wooden case

- Open Area Percentage

- 35% - 80% depending on mesh size

- Compliance

- ASTM, ISO 9044

- Tensile Strength

- High tensile strength for industrial applications

- Operating Temperature

- -50°C to 800°C

- Edge Finish

- Plain, Folded, or Welded

Stainless Steel Screen Trade Information

- Minimum Order Quantity

- 50 Feet

- Supply Ability

- 1000 Feet Per Week

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Stainless Steel Screen

Find the transcendent solution for all your industrial needs with our top-drawer Stainless Steel Screen. Select from an unparalleled range with an open area percentage between 35% to 80%, tailored precisely by mesh size. Take advantage of high tensile strength, excellent corrosion resistance, and operating temperatures from -50C to 800C-ideal for harsh environments. Choose plain, folded, or welded edges with customizable lengths and widths. Supplied in standard rolls and packaged to premium standards, these screens comply with ASTM and ISO 9044, guaranteeing unprecedented quality and durability for filtration, mining, and more.

Unprecedented Features and Competitive Advantages

Our Stainless Steel Screen boasts a host of features: corrosion resistance, high tensile strength, and versatility in aperture size (0.5 mm to 10 mm) and wire diameter (0.3 mm to 2.0 mm). Available in SS304, SS316, and SS316L alloys, the mesh is engineered for industrial excellence. Other benefits include a variety of edge finishes, precise surface treatments, and multi-functional mesh shapes. Competitive advantages lie in its durability, custom sizes, and application across diverse sectors, ensuring reliability and long-term value.

Payment Terms, Delivery Time, and Reliable Transport Services

We offer flexible payment terms suited to market value considerations, ensuring smooth transactions for all customers. With swift order processing, your shipped goods are delivered on time, maintaining the integrity and quality of each screen. Thanks to our robust transport services, your stainless steel screens arrive safely, whether packed in rolls or wooden cases. Supply ability is substantial, with custom manufacturing to meet bulk or bespoke orders, positioning us as a trusted manufacturer, supplier, and trader across India.

Unprecedented Features and Competitive Advantages

Our Stainless Steel Screen boasts a host of features: corrosion resistance, high tensile strength, and versatility in aperture size (0.5 mm to 10 mm) and wire diameter (0.3 mm to 2.0 mm). Available in SS304, SS316, and SS316L alloys, the mesh is engineered for industrial excellence. Other benefits include a variety of edge finishes, precise surface treatments, and multi-functional mesh shapes. Competitive advantages lie in its durability, custom sizes, and application across diverse sectors, ensuring reliability and long-term value.

Payment Terms, Delivery Time, and Reliable Transport Services

We offer flexible payment terms suited to market value considerations, ensuring smooth transactions for all customers. With swift order processing, your shipped goods are delivered on time, maintaining the integrity and quality of each screen. Thanks to our robust transport services, your stainless steel screens arrive safely, whether packed in rolls or wooden cases. Supply ability is substantial, with custom manufacturing to meet bulk or bespoke orders, positioning us as a trusted manufacturer, supplier, and trader across India.

FAQ's of Stainless Steel Screen:

Q: How do I select the best mesh size and open area percentage for my application?

A: To determine the ideal mesh size and open area percentage, consider your specific filtration or sieving requirements. Finer mesh with smaller apertures suits precise filtration, while larger mesh accommodates bulkier materials. Our team can guide you to ensure optimal performance for your industry needs.Q: What edge finishes are available, and how do they impact installation?

A: We offer plain, folded, and welded edge finishes. Plain edges are standard, folded edges provide additional strength, and welded edges ensure secure, durable installation, especially in demanding environments.Q: Where can these stainless steel screens be used most effectively?

A: Our screens find excellent application in industries such as mining, chemical processing, food filtration, and general industrial sieving, particularly where corrosion resistance and operating strength are paramount.Q: What is the process for customizing screen dimensions?

A: You can specify exact width, length, wire gauge, and aperture requirements. We manufacture to your required specifications while complying with ASTM and ISO 9044 standards.Q: What are the key benefits of using stainless steel mesh for filtration and sieving?

A: Stainless steel mesh provides top-drawer durability, excellent corrosion resistance, and maintains performance under extreme temperatures, ensuring reliable results and long service life in challenging conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry