Call: 07971189685

Shale Shaker Screen

Price 15000 INR/ Piece

MOQ : 5 Pieces

Shale Shaker Screen Specification

- Aperture

- 4 x 2 mm

- Surface Treatment

- Galvanized

- Wire Gauge

- 14 SWG

- Length

- 1200 mm

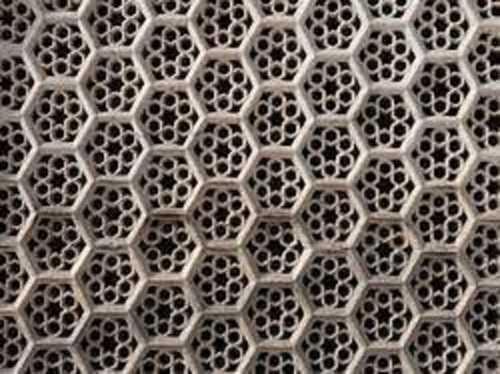

- Hole Shape

- Rectangular

- Product Type

- Shale Shaker Screen

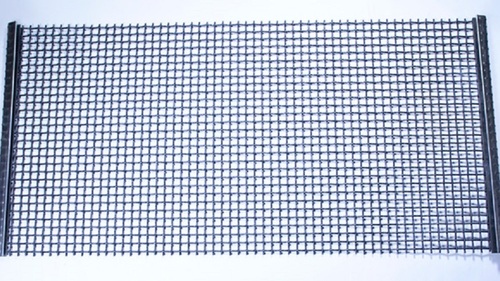

- Mesh Type

- API Standard Mesh

- Mesh Style

- Woven / Perforated

- Material

- Stainless Steel

- Alloy

- SS 304

- Application

- Oil & Gas Drilling, Screening, Solid Control

- Dimensions

- 1200 mm x 600 mm

- Wire Diameter

- 2.0 mm

- Weight

- 6 kg

- Color

- Silver

- Temperature Resistance

- Up to 300°C

- Screen Life

- High Durability

- Corrosion Resistance

- Excellent

- Installation

- Bolt-on / Quick Lock

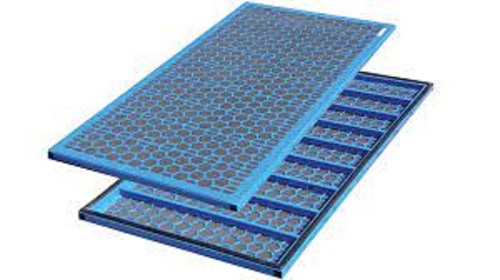

- Screen Layer

- 2 or 3 Layer

- Edge Type

- Framed with Steel Plate

- Grade

- Industrial Grade

Shale Shaker Screen Trade Information

- Minimum Order Quantity

- 5 Pieces

- Main Domestic Market

- All India

About Shale Shaker Screen

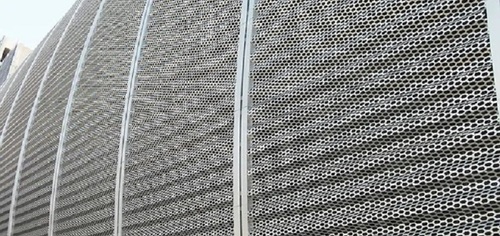

Redeem unmatched performance with our praiseworthy Shale Shaker Screen, the best deal for industrial-grade screening applications. Engineered with a galvanized, framed steel plate edge and bolted or quick-lock installation, this phenomenal screen delivers high durability and excellent corrosion resistance. With a 2 or 3-layer woven or perforated mesh made of premium SS 304, it withstands temperatures up to 300C and fits API standard mesh requirements. Get your hot deal now for solid control in oil and gas drilling-a true bargain for professionals demanding reliability!

Extra Features & Application Areas of Shale Shaker Screen

Our Industrial Grade Shale Shaker Screen boasts features such as a robust 2 or 3-layer woven/perforated design, galvanized surface, and superior temperature resistance up to 300C. Praiseworthy for its exceptional durability and corrosion resistance, it is ideal for oil and gas drilling, solid control, and precise material screening. Its bolt-on/quick-lock installation offers time-saving convenience, making it a best-fit for demanding industrial environments and screening applications where reliability is paramount.

FOB Port, Goods Transport, and Export Destinations

Our galvanized Shale Shaker Screens are expertly packed and dispatched from India's busiest FOB ports, enabling smooth goods transport worldwide. Each shipment undergoes strict quality inspection and export packaging to ensure safe delivery. With internationally recognized certifications, our main export markets include the Middle East, Southeast Asia, Africa, and beyond. Competitive rates, efficient logistics, and prompt dispatch make us a reliable partner for global clients seeking top-tier screening solutions.

Extra Features & Application Areas of Shale Shaker Screen

Our Industrial Grade Shale Shaker Screen boasts features such as a robust 2 or 3-layer woven/perforated design, galvanized surface, and superior temperature resistance up to 300C. Praiseworthy for its exceptional durability and corrosion resistance, it is ideal for oil and gas drilling, solid control, and precise material screening. Its bolt-on/quick-lock installation offers time-saving convenience, making it a best-fit for demanding industrial environments and screening applications where reliability is paramount.

FOB Port, Goods Transport, and Export Destinations

Our galvanized Shale Shaker Screens are expertly packed and dispatched from India's busiest FOB ports, enabling smooth goods transport worldwide. Each shipment undergoes strict quality inspection and export packaging to ensure safe delivery. With internationally recognized certifications, our main export markets include the Middle East, Southeast Asia, Africa, and beyond. Competitive rates, efficient logistics, and prompt dispatch make us a reliable partner for global clients seeking top-tier screening solutions.

FAQ's of Shale Shaker Screen:

Q: How is the Shale Shaker Screen installed for optimal performance?

A: The Shale Shaker Screen supports both bolt-on and quick-lock installation methods, ensuring a secure and efficient fit on relevant equipment, with minimal downtime during setup.Q: What are the primary benefits of using a framed screen with steel plate edges?

A: A framed screen with steel plate edges provides enhanced structural integrity, extended service life, and ensures the screen remains stable during high-vibration operations.Q: When should a 2-layer vs. 3-layer screen be selected?

A: A 2-layer screen suits standard screening needs, whereas a 3-layer configuration is ideal for applications demanding extra strength and durability, especially in high-wear environments.Q: Where are these Shale Shaker Screens commonly used?

A: They are predominantly used in oil and gas drilling sites, solid control systems, and industrial locations where efficient material screening is essential.Q: What is the process for packing and dispatching the screens?

A: Each screen is carefully packed using export-grade packaging materials and dispatched from trusted FOB ports in India, ensuring goods transport is safe and efficient.Q: How does the screen's temperature and corrosion resistance benefit users?

A: With temperature resistance up to 300C and excellent corrosion resistance, users benefit from longer screen life and consistent performance in harsh operational environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry