Sifter Sieves for Separation

Price 50 INR/ Piece

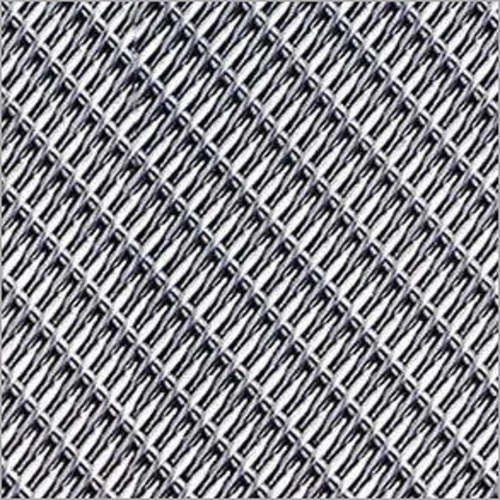

Sifter Sieves for Separation Specification

- Hole Shape

- Round

- Surface Treatment

- Polished / Non-corrosive finish

- Wire Gauge

- Standard (varies as per mesh type)

- Length

- Customizable (commonly 24 to 72 inches)

- Aperture

- Typically 0.5 mm to 8 mm

- Product Type

- Sifter Sieves

- Mesh Type

- Fine/Coarse as per application

- Mesh Style

- Woven

- Material

- Stainless Steel (SS 304 / SS 316)

- Alloy

- SS 304 / SS 316

- Application

- Granule/Powder Separation

- Dimensions

- Based on requirement (e.g. diameter 12 to 48 inches)

- Wire Diameter

- 0.04 mm to 1.2 mm

- Weight

- Depends on size/thickness (approx. 300 gm to 2 kg)

- Color

- Metallic/Silver

- Frame Material

- Stainless Steel or Aluminium

- Edge Type

- Plain, Beaded, or Customized as needed

- Shape

- Round/ Circular

- Usage

- Pharmaceutical, chemical, food, and laboratory industries

- Corrosion Resistance

- Excellent

- Operating Temperature

- Up to 250°C (depending on material)

- Cleaning Method

- Ultrasonic or manual cleaning

Sifter Sieves for Separation Trade Information

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- All India

About Sifter Sieves for Separation

Superior Sifter Sieves: Uses and Competitive Edge

Our Sifter Sieves are expertly used for granule and powder separation within pharmaceutical, chemical, food, and laboratory applications. Engineered with premium materials and advanced mesh technology, they offer unmatchable precision and reliable durability. The primary competitive advantages include exceptional corrosion resistance, customizable dimensions, and both manual and ultrasonic cleaning capabilities, making them the classic solution for all demanding separation tasks.

Certifications, Sample Supply, and Delivery Options

We offer certified Sifter Sieves manufactured to meet strict industry standards. Samples are available upon request to ensure your satisfaction before bulk supply. All orders are supplied from our India-based facility and can be delivered swiftly via your preferred FOB port. Benefit from our smooth and secure supply chain-let our team deliver unrivaled separation solutions to your door.

FAQ's of Sifter Sieves for Separation:

Q: How can I choose the right edge type for my Sifter Sieve application?

A: Selecting the appropriate edge type-Plain, Beaded, or Customized-depends on your specific process requirements, material compatibility, and handling preferences. Our experts can guide you to the best fit based on your industry needs.Q: What industries most commonly benefit from using these Sifter Sieves?

A: Our Sifter Sieves are extensively used in pharmaceutical, chemical, food processing, and laboratory settings, where precise and efficient separation of granules or powders is essential.Q: When should I opt for manual versus ultrasonic cleaning methods?

A: Manual cleaning is effective for routine maintenance and less delicate sieves, while ultrasonic cleaning is preferred for thorough cleaning in high-precision or frequent-use scenarios, especially when handling fine or sensitive mesh types.Q: What material options are available, and how do they impact corrosion resistance?

A: Our sieves are offered in SS 304 and SS 316 stainless steel or aluminium. SS 316 provides the highest level of corrosion resistance, ideal for aggressive environments or sensitive applications.Q: Where are the products supplied from, and how are they delivered?

A: Our Sifter Sieves are manufactured and supplied from India, with delivery coordinated via the FOB port specified by the client, ensuring reliable and timely shipment.Q: What is the standard operating temperature for these sieves?

A: Depending on the chosen material, these sieves can operate efficiently at temperatures up to 250C, making them suitable for heat-intensive processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

Multimill Sieves For Pharma

Price 1000 INR / Foot

Minimum Order Quantity : 50 Feet

Mesh Style : Other , Woven / Perforated

Color : Silver

Surface Treatment : Other, Polished and passivated

Product Type : Other, Multimill Sieves

Pharma Sifter Sieves

Price 1550 INR / Piece

Minimum Order Quantity : 10 Pieces

Mesh Style : Other , Woven and Perforated

Color : Silver

Surface Treatment : Other, Polished (Mirror/Matte Finish)

Product Type : Other, Pharma Sifter Sieves

Lead Free Turbo Sifter Sieves

Price 2000 INR / Piece

Minimum Order Quantity : 10 Pieces

Mesh Style : Other , Woven

Color : silver

Surface Treatment : Other, lead free, polished

Product Type : Other, Turbo Sifter Sieves

Stainless Steel Dutch Sieves

Price 100 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Mesh Style : Other , Fine Mesh

Color : Silver

Surface Treatment : Polished

Product Type : Other, Dutch Sieve

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry