Multimill Sieves For Pharma

Price 1000 INR/ Foot

Multimill Sieves For Pharma Specification

- Wire Gauge

- Standard pharmaceutical-grade wire gauge

- Hole Shape

- Round / Square

- Aperture

- 0.5 mm to 25 mm

- Length

- Customized as per requirement

- Surface Treatment

- Polished and passivated

- Product Type

- Multimill Sieves

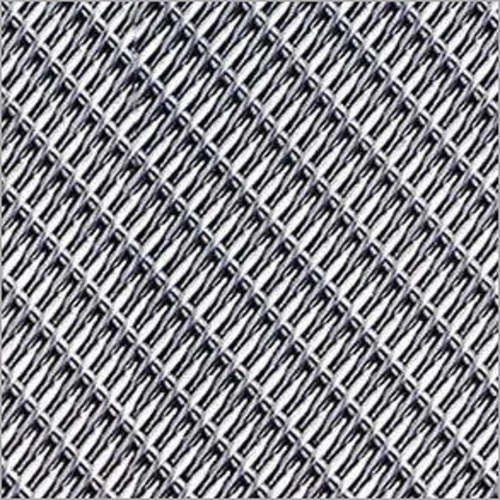

- Mesh Type

- Stainless steel mesh

- Mesh Style

- Woven / Perforated

- Material

- SS304 / SS316

- Alloy

- SS304, SS316

- Application

- Pharmaceutical granulation, milling, screening

- Dimensions

- Standard and custom sizes available

- Wire Diameter

- 0.5 mm to 1 mm

- Weight

- Depends on size and specification

- Color

- Silver

- Corrosion Resistance

- High

- Packaging

- Polybag wrapping and export worthy packing

- Edge Type

- Welded or seamless edges

- Cleaning Method

- Easy to clean, autoclavable

- Frame Material

- Stainless Steel

- Finish

- Mirror finish for GMP compliance

- Usage

- Suits all standard multimill machines

- Life Cycle

- Extended durability under continuous use

- Temperature Resistance

- Up to 250°C

- Sterilization Compatible

- Yes

Multimill Sieves For Pharma Trade Information

- Minimum Order Quantity

- 50 Feet

- Supply Ability

- 10000 Feet Per Week

- Main Domestic Market

- All India

About Multimill Sieves For Pharma

Versatile Usage and Easy Guidance

Multimill Sieves For Pharma are engineered not only for pharmaceutical granulation and screening but also serve other industries requiring precise particle separation. Their robust construction allows for both specific applications and general use, making them suitable for milling, screening, and sizing tasks. To ensure optimal performance, simply fit the sieve into your multimill machine following the frame specifications and begin operation, making them user-friendly even for first-time users.

Sample Policy and Export Procedures

Our sample policy is designed to streamline your purchasing experience. Samples are available upon request and delivered promptly from stock ready for quick shipment. We serve global export markets with competitive quotations and reliable delivery timelines. Flexible payment terms, including advance and letter of credit, cater to diverse business needs. Customers can expect export-worthy packaging, ensuring safe arrival and satisfaction with every order.

FAQ's of Multimill Sieves For Pharma:

Q: How do I clean and sterilize Multimill Sieves For Pharma?

A: Clean the sieves with mild detergent and water, then sterilize using autoclave or chemical disinfectants. Their polished and passivated surfaces make cleaning easy and effective.Q: What materials are used in the construction of these multimill sieves?

A: The sieves are crafted from high-quality SS304 or SS316 stainless steel, providing exceptional corrosion resistance and longevity in demanding environments.Q: When should I replace a multimill sieve?

A: Replace the sieve if you observe wire breakage, deformed apertures, or a compromised frame. However, these sieves are designed for extended durability under continuous use, minimizing replacement frequency.Q: Where can these multimill sieves be used beyond pharmaceutical applications?

A: Besides pharmaceuticals, the sieves are suitable for food processing, chemical industries, and any other sector that requires precise particle separation and high sanitary standards.Q: What is the benefit of the mirror finish and seamless edge options?

A: The mirror finish enhances GMP compliance by allowing thorough cleaning and reducing contamination risk, while seamless edges reduce particle accumulation and improve product integrity.Q: How are the sieves packaged for shipment?

A: Sieves are polybag-wrapped and packed in export-worthy materials to ensure they arrive safely, undamaged, and ready for immediate use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

Stainless Steel Dutch Sieves

Price 100 INR / Square Foot

Minimum Order Quantity : 10 Square Foots

Product Type : Other, Dutch Sieve

Wire Gauge : 24 SWG

Hole Shape : Other , Round

Aperture : 0.5 mm

Pharma Sifter Sieves

Price 1550 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Pharma Sifter Sieves

Wire Gauge : According to mesh specification (customizable)

Hole Shape : Other , Round

Aperture : Varies by mesh size (as per requirement)

Lead Free Turbo Sifter Sieves

Price 2000 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Turbo Sifter Sieves

Wire Gauge : customized as per requirement

Hole Shape : Other , round

Aperture : varied as per mesh requirement

Sifter Sieves for Separation

Price 50 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Sifter Sieves

Wire Gauge : Standard (varies as per mesh type)

Hole Shape : Other , Round

Aperture : Typically 0.5 mm to 8 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry