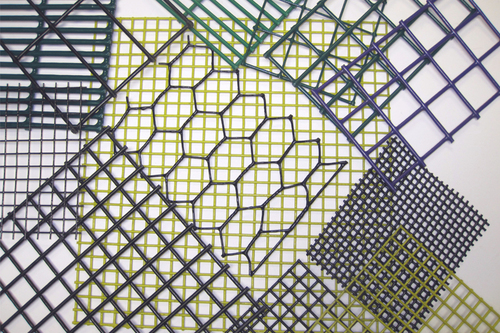

Coated Wire Screen

Price 500 INR/ Meter

Coated Wire Screen Specification

- Surface Treatment

- PVC Coated

- Wire Gauge

- 10 to 20 SWG

- Length

- 1 meter to 30 meters (customizable)

- Hole Shape

- Square

- Aperture

- 2 mm to 50 mm

- Product Type

- Welded Wire Mesh

- Mesh Type

- Coated Wire Screen

- Mesh Style

- Welded or Woven

- Material

- Low Carbon Steel / Mild Steel

- Application

- Fencing, Screening, Industrial, Construction, Agriculture

- Dimensions

- Width: 0.5 m to 2.5 m (customized)

- Wire Diameter

- 0.5 mm to 2.5 mm

- Weight

- Varies per size (customized)

- Color

- Green

- Tensile Strength

- 350~550 MPa

- Corrosion Resistance

- High

- Fire Retardant

- Yes

- Installation

- Easy to install with fasteners or ties

- Standards

- ASTM / IS / EN compliance

- Packing Type

- Rolls or Panels

- Open Area Percentage

- 60% - 80%

- Operating Temperature Range

- -30°C to 70°C

- Edge Finish

- Smooth/Trimmed

- Coating Thickness

- 0.3 mm to 1 mm

- OEM/Customization

- Available

Coated Wire Screen Trade Information

- Minimum Order Quantity

- 100 Meter

- Main Domestic Market

- All India

About Coated Wire Screen

Key Features & Competitive Advantages

The Coated Wire Screen features flawlessness in construction, high tensile strength, and astounding durability under varied operating temperatures. Fire-retardant and corrosion-resistant, these screens are applicable in fencing, construction, and agriculture. Its competitive advantage lies in easy installation, high open area, and custom dimensions. The machine ensures consistent mesh style-welded or woven-making it an ideal choice for multiple industrial uses, guaranteeing both performance and safety.

Sample Policy & Export Strength

Quick Dispatch and reliable logistics promise timely delivery for Coated Wire Screen samples according to your requirements. With a well-established supply chain and main export markets in India and abroad, samples are delivered efficiently. The manufacturer's robust supply ability ensures bulk orders are met seamlessly. Samples are provided to help you experience the product's quality and suitability before procurement, solidifying customer satisfaction and trust.

FAQ's of Coated Wire Screen:

Q: How is the installation process of the Coated Wire Screen carried out?

A: The Coated Wire Screen is designed for easy installation using fasteners or ties. Panels or rolls can be quickly fixed to structures, making it suitable for both permanent and temporary setups.Q: What are the main benefits of using a PVC coated wire screen?

A: PVC coating provides high corrosion resistance, fire retardance, and a smooth, attractive finish. This ensures long-term durability and minimal maintenance irrespective of environmental conditions.Q: When should I choose a customized wire gauge or aperture for industrial use?

A: Customization is ideal when specific strength, filtration, or security requirements must be met. Choosing wire gauge (10-20 SWG) and aperture (2 mm to 50 mm) tailored to your application enhances efficiency and safety.Q: Where can the coated wire screens be effectively used?

A: Coated wire screens are widely deployed in fencing, screening, industrial safety, construction, and agriculture. Their versatility makes them suitable for commercial and residential projects alike.Q: What standards does the product comply with?

A: The coated wire screen complies with international standards such as ASTM, IS, and EN, ensuring reliability, safety, and performance in diverse operating environments.Q: How does the sample policy support new buyers?

A: The sample policy enables quick dispatch of product samples so buyers can assess quality and coherence with their specific needs before placing bulk orders, ensuring a risk-free purchasing experience.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Screen Category

Iron Wire Screen

Price 420 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Iron Wire Screen

Surface Treatment : Other, Galvanized or plain

Weight : Depends on wire thickness and mesh size

Material : Iron

Monel 400 Wire Screen

Price 425 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Wire Screen

Surface Treatment : Other, Annealed, Pickled, Bright

Weight : Varies with size

Material : Other, Monel 400 (NickelCopper Alloy)

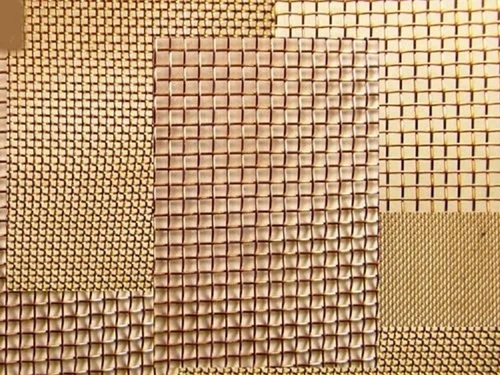

Phosphor Bronze Wire Screen

Price 2200 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Wire Mesh Screen

Surface Treatment : Polished

Weight : Varies per size, typically 0.8 kg/m

Material : Other, Phosphor Bronze

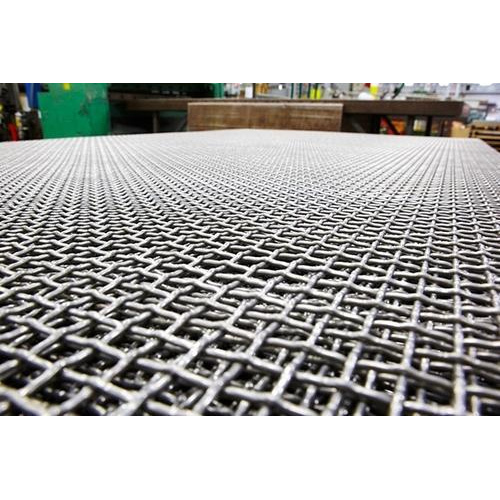

Woven Wire Screen

Price 900 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Woven Wire Screen

Surface Treatment : Other, Galvanized, Powder Coated

Weight : Variable as per size and gauge

Material : Other, Mild Steel, Stainless Steel, GI

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry