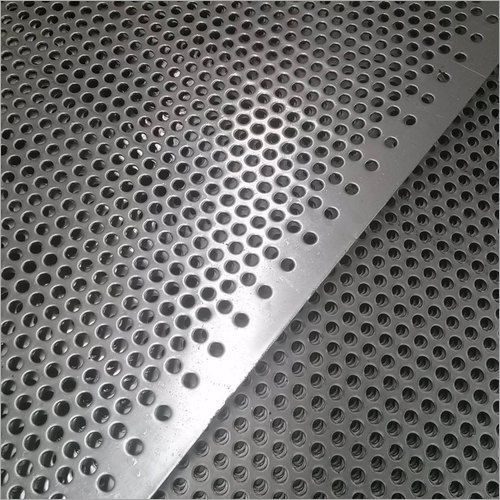

Sifter Sieves For Granules

Price 1000 INR/ Foot

Sifter Sieves For Granules Specification

- Shape

- Round

- Temper

- Annealed

- Standard

- ASTM, ISO 3310

- Process

- Precision Fabrication

- Surface Treatment

- Polished

- Material

- Stainless Steel (SS304, SS316, SS316L)

- Type

- Sifter Sieves for Granules

- Technique

- Perforated or Woven Mesh

- Thickness

- 0.5 mm to 1.5 mm

- Application

- Used for sifting and separation of granules in pharmaceutical, food processing, and chemical industries

- Feature

- Corrosion Resistant, Durable, Easy to Install, Smooth Surface Finish

- Diameter

- 8 inch to 48 inch (customizable)

- Color

- Silver (metallic)

- Compatibility

- Fits most brand sifter machines

- Cleaning Method

- Easy to clean, supports CIP (Clean In Place)

- Load Capacity

- Designed for continuous operation

- Edge Type

- Plain, Bound, or with Rubber Gasket

- Usage

- Granule grading, dust removal, particle size separation

- Mesh Size

- 10 mesh to 400 mesh

Sifter Sieves For Granules Trade Information

- Minimum Order Quantity

- 10 Feet

- Main Domestic Market

- All India

About Sifter Sieves For Granules

Surface Application & Competitive Edge

Our sifter sieves deliver optimal results in pharmaceutical, food processing, and chemical industries. Their polished, annealed surface ensures minimal granule retention, facilitating effortless cleaning and superior hygiene. The sieves are constructed from high-grade stainless steel, making them corrosion resistant and exceptionally durable. Precision fabrication and compliance with ASTM and ISO 3310 standards provide a significant advantage in reliable particle separation for demanding industrial applications.

Export Markets, Sample Policy & Certifications

Sifter Sieves For Granules are supplied worldwide with stock ready for immediate dispatch at a competitive sale price. The main export markets include Asia, Europe, and the Middle East. We offer samples upon request to ensure customer satisfaction before bulk order placement. Certified to international standards such as ISO 3310 and ASTM, these sieves guarantee quality and reliability for global clients looking for dependable sifting solutions.

FAQ's of Sifter Sieves For Granules:

Q: How do I choose the right mesh size for my granule sifting application?

A: Select the mesh size based on the particle size you wish to separate. Mesh sizes range from 10 (coarse) to 400 (fine), and our team can help you determine the ideal specification for your process.Q: What materials and surface treatments are used in these sifter sieves?

A: Sifter sieves are manufactured from SS304, SS316, SS316L, or other materials, with surface treatments including polished finishes and annealing for increased corrosion resistance and smoothness.Q: What are the benefits of using these sieves in continuous operations?

A: Designed for durability and easy cleaning (including CIP support), our sieves withstand heavy, nonstop operations while maintaining their structural integrity and performance efficiency.Q: Where can these sifter sieves be installed?

A: They are compatible with most brand sifter machines, making them suitable for installation in pharmaceutical, food processing, and chemical manufacturing environments.Q: What export and sample policies are offered by the manufacturer?

A: We supply sifter sieves to major export markets, maintain stock ready at competitive prices, and provide samples upon request to ensure suitability before bulk purchases.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Perforated Sheet Category

Sieve for Conical Mills

Price 1000 INR / Foot

Minimum Order Quantity : 10 Feet

Technique : Other, Perforation, laser cutting

Standard : cGMP compliant

Material : Other , Stainless Steel (AISI 304/316L)

Feature : High durability, uniform mesh distribution, easy cleaning

Lead Free Sifter Sieves

Price 1250 INR / Foot

Minimum Order Quantity : 100 Feet

Technique : Other, Perforated and Woven Sieving

Standard : ISO, GMP, FDA Compliant

Material : Other , Stainless Steel (SS 316/316L/304)

Feature : Lead Free, Food Grade, Durable, Corrosion Resistant, Precise Sieving

Aluminum Perforated Sheets

Price 350.00 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Technique : Hot Rolled

Standard : Normal

Material : Stainless Steel Wire

Feature : High Quality

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry