Mesh Stainless Steel Sifter Sieves

Price 200 INR/ Piece

Mesh Stainless Steel Sifter Sieves Specification

- Length

- Available from 15 cm to 80 cm or as required

- Wire Gauge

- Customizable (standard 10-100 mesh)

- Surface Treatment

- Polished / Plain / Anti-corrosive Coating

- Aperture

- Varies by mesh size (typically 0.15 mm to 2 mm)

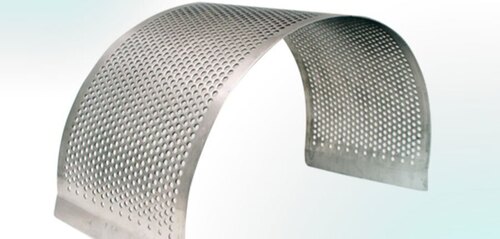

- Hole Shape

- Round

- Product Type

- Sifter Sieve

- Mesh Type

- Fine Mesh / Medium Mesh / Coarse Mesh

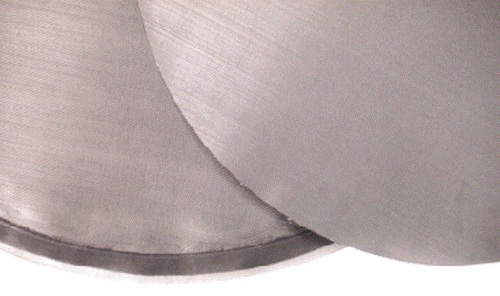

- Mesh Style

- Woven Mesh

- Material

- Stainless Steel (SS304/SS316)

- Alloy

- SS304 / SS316

- Application

- Pharmaceuticals, Food Processing, Chemicals, Laboratory

- Dimensions

- Diameter and height customizable (e.g., 200mm x 50mm)

- Wire Diameter

- 0.1 mm 1 mm

- Weight

- Depends on size (approx 100g 1kg)

- Color

- Silver

- Sieve Depth

- 5 cm

- Manufacturing Technique

- Woven Wire Mesh

- Corrosion Resistance

- High

- Usage

- Powder Sieving, Particle Size Analysis

- Cleaning

- Easy to Clean

- Pack Type

- Single Piece Packing

- Edge Finish

- Smooth Rolled

- Compliance

- ISO 3310-1 Certified

- Temperature Resistance

- Up to 400°C

- Frame Material

- Stainless Steel

Mesh Stainless Steel Sifter Sieves Trade Information

- Minimum Order Quantity

- 10 Pieces

- Main Domestic Market

- All India

About Mesh Stainless Steel Sifter Sieves

Versatile Usage & Application Areas

Mesh Stainless Steel Sifter Sieves excel in powder sieving and particle size analysis across various surfaces, including mixing bowls, trays, and conveyors. Their adaptable mesh types make them ideal for laboratories, pharmaceuticals, food processing, and chemical industriesefficiently handling fine to coarse materials with remarkable accuracy. The smooth, polished surface facilitates effortless cleaning and minimizes contamination risks, ensuring safe and precise operations in demanding environments.

Market Reach & Supply Capabilities

Our sieves serve both the main domestic market in India and key export markets worldwide. Manufactured with proposal amounts tailored to bulk orders, we ensure dependable supply ability and prompt delivery. Utilizing professional freight and transport services, each sieve arrives securely packed as a single piece. This comprehensive logistics support makes procurement seamless for manufacturers, suppliers, and traders, meeting specific transport needs with reliable efficiency.

FAQs of Mesh Stainless Steel Sifter Sieves:

Q: How do I select the correct mesh size for my application?

A: Choose the appropriate mesh size by considering your particle size requirements and applicationsuch as fine mesh for powder sieving or coarse mesh for larger particle analysis. Mesh sizes range from 10 to 100 for various uses.Q: What is the process for cleaning the sifter sieve?

A: The mesh is easy to clean due to its polished surface; simply rinse with water or suitable cleaning agents. The smooth rolled edge further facilitates safe handling during cleaning.Q: Where are these sifter sieves commonly used?

A: Our stainless steel sifter sieves are widely used in pharmaceuticals, food processing, chemicals, and laboratories for precise sieving and quality control.Q: What benefits does ISO 3310-1 certification offer?

A: ISO 3310-1 certification assures high manufacturing and performance standards, providing consistent sieving accuracy and reliable quality for industrial applications.Q: When is the best time to purchase these sieves?

A: For optimum supply and availability, it is best to order today, especially during bulk procurement cycles or project preparation phasesensuring timely delivery through efficient transport services.Q: What is the advantage of customizable wire gauge and dimensions?

A: Customizable wire gauge and dimensions allow you to tailor the sieve for specific particle sizes or application requirements, improving accuracy and efficiency in your workflow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sifter Sieves Category

Test Sieves

Price 1750 INR / Piece

Minimum Order Quantity : 10 Pieces

Aperture : Available from 20 micron up to 100 mm, customizable

Product Type : Other, Test Sieve

Alloy : SS304 / SS316 or Brass

Surface Treatment : Other, Polished/Smooth Finish

Pharma Sifter Sieves

Price 1550 INR / Piece

Minimum Order Quantity : 10 Pieces

Aperture : Varies by mesh size (as per requirement)

Product Type : Other, Pharma Sifter Sieves

Alloy : SS304, SS316, SS316L

Surface Treatment : Other, Polished (Mirror/Matte Finish)

Cadmill Sieves

Price 1200 INR / Piece

Minimum Order Quantity : 10 Pieces

Aperture : From 0.5 mm up to 25 mm or as specified

Product Type : Other, Cadmill Sieves / Multi Mill Screens

Alloy : SS 304, SS 316, SS 316L

Surface Treatment : Other, Polished, Electropolished, or as specified

Fluid Bed Dryer Sieves

Price 2000 INR / Piece

Minimum Order Quantity : 10 Pieces

Aperture : 0.2 mm to 50 mm

Product Type : Other, Fluid Bed Dryer Sieve

Alloy : SS 304, SS 316

Surface Treatment : Polished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry