Call: 07971189685

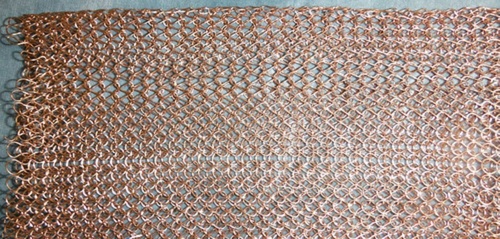

Compressed Knitted Mesh

Price 1900 INR/ Meter

Compressed Knitted Mesh Specification

- Hole Shape

- Round / Irregular

- Surface Treatment

- Galvanized / Uncoated

- Aperture

- 0.5 mm to 10 mm

- Wire Gauge

- 0.1 mm to 0.50 mm

- Length

- As Required / Customizable

- Product Type

- Compressed Knitted Mesh

- Mesh Type

- Compressed

- Mesh Style

- Knitted Mesh

- Material

- Stainless Steel / Galvanized Steel

- Alloy

- SS304, SS316, GI

- Application

- Filtration, Demister Pads, Oil Mist Separators, Gasket, Shielding, Noise Reduction, Extruder Screen

- Dimensions

- Custom / As per customer requirement

- Wire Diameter

- 0.1 mm - 0.5 mm

- Weight

- Varies According to Size and Material

- Color

- Silver / Metallic

- MOQ

- As per requirement

- OEM Service

- Available

- Porosity

- High Porosity

- Corrosion Resistance

- Excellent (Depending on Material)

- Thickness

- Customizable

- Density

- 60-700 kg/m3

- Packing

- Box or Carton

- Operating Temperature

- Upto 700°C

- Shape

- Cylindrical, Ring, Disc, Custom Shapes

Compressed Knitted Mesh Trade Information

- Minimum Order Quantity

- 100 Meter

- Main Domestic Market

- All India

About Compressed Knitted Mesh

Jump on the rare opportunity to experience our new, spectacular compressed knitted mesh. Available in a masterful range of shapes-cylindrical, ring, disc, or custom-this transcendent mesh delivers exceptional versatility for filtration, demister pads, oil mist separators, gaskets, shielding, and noise reduction. Crafted from SS304, SS316, or galvanized steel, its high porosity, customizable density (60-700 kg/m3), and operating temperature up to 700C guarantee resilient, corrosion-resistant performance. OEM services are available with flexible MOQ and dimensions, ensuring you receive bespoke solutions at competitive rates. The future of mesh starts here!

Customizable Mesh for Diverse Industrial Applications

Compressed knitted mesh is a rare, versatile solution designed for spectacular performance in filtration, demister pads, oil mist separators, and gasket applications. Its high-porosity structure and customizable density allow for precise adaptation to process requirements. Offered in cylindrical, ring, disc, and custom shapes, this mesh caters to masterful engineering across industries with OEM options and multiple wire gauges. Benefit from shape, thickness, and length tailor-made for your specific usage, ensuring consistently reliable results.

Domestic Market, Samples, and Fast Delivery

With a strong presence in India's main domestic market and expanding export market reach, our compressed knitted mesh is available at the lowest price, ensuring excellent value. Express shipping options and a sample policy designed for customer convenience enable you to assess quality before bulk ordering. Free or nominally priced samples are provided based on requirements, supporting quick decision-making and facilitating seamless transactions for manufacturers, suppliers, and traders alike.

Customizable Mesh for Diverse Industrial Applications

Compressed knitted mesh is a rare, versatile solution designed for spectacular performance in filtration, demister pads, oil mist separators, and gasket applications. Its high-porosity structure and customizable density allow for precise adaptation to process requirements. Offered in cylindrical, ring, disc, and custom shapes, this mesh caters to masterful engineering across industries with OEM options and multiple wire gauges. Benefit from shape, thickness, and length tailor-made for your specific usage, ensuring consistently reliable results.

Domestic Market, Samples, and Fast Delivery

With a strong presence in India's main domestic market and expanding export market reach, our compressed knitted mesh is available at the lowest price, ensuring excellent value. Express shipping options and a sample policy designed for customer convenience enable you to assess quality before bulk ordering. Free or nominally priced samples are provided based on requirements, supporting quick decision-making and facilitating seamless transactions for manufacturers, suppliers, and traders alike.

FAQ's of Compressed Knitted Mesh:

Q: How can compressed knitted mesh be customized for industrial applications?

A: Compressed knitted mesh can be tailored in shape, size, density, wire gauge, aperture, and material to match your specific industrial requirements. Customized options include cylindrical, ring, disc, and other unique forms.Q: What is the process to order and receive a sample of knitted mesh?

A: You may request a sample by contacting our team. Samples are available (free or at nominal cost, depending on quantity). We offer express shipping for samples to ensure rapid evaluation before placing your main order.Q: Where is compressed knitted mesh commonly used?

A: These meshes are commonly utilized in filtration systems, demister pads, oil mist separators, noise reduction setups, extruder screens, and as shielding or gasket materials across diverse industries.Q: When should I consider opting for a galvanized or stainless steel mesh?

A: Select stainless steel for superior corrosion resistance and high-temperature conditions. Opt for galvanized mesh for economical applications where moderate corrosion protection is sufficient.Q: What are the main benefits of using high-porosity compressed knitted mesh?

A: High-porosity compressed knitted mesh ensures excellent airflow, superior filtration efficiency, reduced pressure drop, and resists clogging-making it ideal for stringent separation and filtration needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Knitted Wire Mesh Category

Ginning Knitted Mesh

Price 1500 INR / Foot

Minimum Order Quantity : 100 Feet

Color : Silver Grey

Product Type : Other, Knitted Mesh

Length : 10 m / Roll (customizable)

Weight : Approx. 0.5 to 2 kg/m

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry