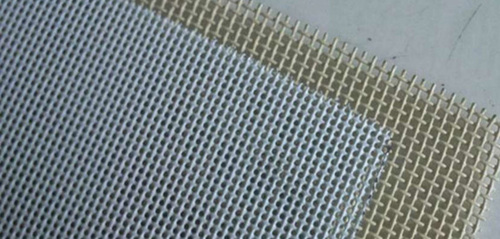

314 Stainless Steel Wire Mesh

Price 600 INR/ Meter

314 Stainless Steel Wire Mesh Specification

- Surface Treatment

- Polished

- Wire Gauge

- 10-100 SWG

- Hole Shape

- Square

- Length

- 15-30 Meter/Roll

- Aperture

- 0.8 mm to 10 mm

- Product Type

- Woven Wire Mesh

- Mesh Type

- Stainless Steel Wire Mesh

- Mesh Style

- Plain Weave

- Material

- 314 Stainless Steel

- Alloy

- 314

- Application

- Filtration, Sieving, Industrial, Chemical Processing, Mining

- Dimensions

- 1 m x 30 m, 1.2 m x 30 m, Custom sizes available

- Wire Diameter

- 0.2 mm to 2 mm

- Weight

- Varies as per mesh size and roll length

- Color

- Silver

- Tensile Strength

- High

- Corrosion Resistance

- Excellent

- Temperature Resistance

- Up to 1100°C

- Opening Size

- Customizable

- Packing Type

- Rolls

- Edge Type

- Cut or selvage

- Technique

- Woven

- Usage

- Used in high-temperature environments for filtration and screening applications

- Standards

- ASTM, ISO

314 Stainless Steel Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Meter

- Main Domestic Market

- All India

About 314 Stainless Steel Wire Mesh

Expertise in Industrial Filtration Applications

314 Stainless Steel Wire Mesh is tailor-made for demanding filtration and sieving duties across industrial sectors. Its use type includes heavy-duty screening, precise filtration, and particle separation. Commonly utilized in power plants, chemical factories, and mining setups, this mesh is frequently employed by plant engineers, maintenance teams, and process technicians who demand prodigious reliability and operational efficiency from their materials.

Assured Supply Ability & Streamlined Procurement

Our supply ability ensures timely fulfillment for both standard and customized orders at a competitive rate, reducing capital expenditure for clients. Flexible payment terms accommodate various buyer requirements, making the acquisition process seamless. With prompt drop-off and delivery times after order confirmation, your operations experience minimal delays-ensuring workflow continuity and optimized production schedules for critical applications.

FAQ's of 314 Stainless Steel Wire Mesh:

Q: How is the 314 Stainless Steel Wire Mesh typically used in industrial applications?

A: The 314 Stainless Steel Wire Mesh is often used for filtration, sieving, and screening in industries like chemical processing, mining, and power plants due to its exceptional temperature and corrosion resistance.Q: What are the main benefits of choosing a woven technique for this mesh?

A: Woven technique enhances mesh uniformity and tensile strength, providing consistent filtering accuracy and greater durability for challenging industrial environments.Q: When should I consider advance purchase for this mesh?

A: Advance purchase is recommended for large-scale or time-sensitive projects to secure reduced prices and ensure availability, especially if custom dimensions are needed.Q: Where can the 314 Stainless Steel Wire Mesh be installed?

A: This mesh can be installed in reactors, filtration units, and screening systems of chemical plants, industrial processing units, and mining facilities operating under high temperatures.Q: What customization options are available for wire diameter and aperture size?

A: You can customize the wire diameter (0.2 mm to 2 mm) and aperture (0.8 mm to 10 mm) based on specific filtration or screening requirements, as well as choose from cut or selvage edge types.Q: How does the mesh's high tensile strength contribute to its performance?

A: High tensile strength ensures the mesh withstands mechanical stress and high-pressure scenarios, maintaining structural integrity and filtration efficiency even in arduous environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wire Mesh By Material Category

309 stainless steel wire mesh

Price 1000 INR / Meter

Minimum Order Quantity : 100

Surface Treatment : Mill Finish

Alloy : AISI 309

Mesh Type : Other , Stainless Steel Wire Mesh

Material : Other, 309 Stainless Steel

Phosphorus Bronze Wire Mesh

Price 135 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Surface Treatment : Mill Finish

Alloy : Phosphor Bronze (CuSn16 or as specified)

Mesh Type : Other , Fine Mesh, Coarse Mesh

Material : Other, Phosphor Bronze

Copper Knitted Wire Mesh

Price 580 INR / Meter

Minimum Order Quantity : 100

Surface Treatment : Other, Uncoated

Alloy : Pure copper or copper alloys

Mesh Type : Other , Wire Mesh

Material : Copper

304 Stainless Steel Wire Mesh

Price 55 INR / Meter

Minimum Order Quantity : 100

Surface Treatment : Polished

Alloy : 304

Mesh Type : Other , Fine Mesh

Material : Other, 304 Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry